Photovoltaics have become a very hot topic in recent years. We will give a closer look at the mechanism of operation and what conditions must be met for the sun's rays to power our home with clean and green energy.

Photovoltaics in a few words can be described as the process of generating electricity from a completely free and renewable source - solar radiation.

We remember the first examples of the use of photovoltaics back in our school days - the sun's rays powered our calculators, watches, lamps. Over the years, photovoltaics have also made their way into larger equipment, such as traffic signals, parking meters, city bike stations, as well as heating and space and water heating systems in buildings. Given the current situation of climate policy, restrictions, subsidies, rising prices and constantly developing technology, everyone can realistically reap the benefits of renewable energy sources, including photovoltaics.

Learn more about our FAQs. Learn the basics about photovoltaics.

Silicon, which acts as a semiconductor of electrical charge as a result of external factors - temperature or insolation - is most often used to manufacture cells. Photovoltaic cells are an integral and, when combined into photovoltaic modules, one of the most important parts of the entire photovoltaic installation.

The cells are where the transformation of solar energy into direct current takes place. A photovoltaic panel is the component we most often see placed on the roofs of houses and other buildings, and it consists of modules that power a single inverter. Mounting on the roof or on the ground is made possible by a support structure, which also has the task of ensuring the stability of the entire system. It should be remembered that the panel is exposed daily to varying weather conditions - rain, hail, snow, wind, etc.

A bi-directional meter is responsible for measuring bi-directional current flow (i.e., analyzing the amount of electricity produced by a domestic photovoltaic system and drawn from the power grid). There may be a situation in which our installation produces too much or too little energy in relation to demand. If there is excess energy, it is transferred to the power grid, and we, as the supplier, can collect 80% of the energy produced by our installation. The situation involves a system of discounts for prosumers - people who generate energy for their own needs. Here are three scenarios of applied scenarios:

1. for an installation whose power does not exceed 10kWp, the ratio of 1:0.8 applies - in practice, this means that for every 1kWh given to the grid, the owner of the micro-generation plant (and thus the prosumer) can collect 0.8 kWh.

2 Installation, the power of which oscillates between 10 and 50 kWp prosumer will be billed at a ratio of 1:0.7. The 1 kwH put into the grid will allow 0.7 kWh to be received.

(3) When the demand cannot be fully covered by the generated and received difference is compensated by energy from the network in a ratio of 1:1.

We already have a basic knowledge of how domestic photovoltaic systems work. Time to lean into the construction and operation of the aforementioned photovoltaic cell .

A few paragraphs earlier it was mentioned that the cells are made of a semiconductor, which is silicon. Under the influence of energy, it changes from an insulator to a conductor. Three types of links can be distinguished.

Silicon with a highly ordered structure devoid of numerous defects builds monocrystalline cells. They are characterized by the efficiency of converting solar energy into electricity (we call it efficiency) at the highest level. The efficiency of the module can be determined at 15%-19%, which w means that the energy of solar radiation falling on 1m2 of the cell in 15% is converted into electricity.

Immediately following monocrystalline cells are polycrystalline cells, which have a higher number of defects and a less ordered structure of the semiconductor - silicon. The efficiency of polycrystalline cells ranks at 14%-16%.

The last type of cells are amorphous - the principle is similar - in their number of defects is even greater, and the silicon is not in the form of a crystal, which leads to the most chaotic structure, making the efficiency from 9% to 14%.

The first two types of cells: mono-crystalline and poly-crystalline can be successfully implemented in installations placed on the roofs of houses or in gardens. As the efficiency of the cells increases, so does their price and also the sophistication of implementation. However, polycrystalline cells are most commonly found in home power plants.

Photovoltaic cells range in power from tens of milliwatts to a few watts. These are what power the small electronics. In order to obtain a synergistic effect, the cells are connected to each other in modules. The cells are coated with EVA and PET films, then placed under tempered glass and mounted in an aluminum frame. This ensures that the panel is protected from damage and the construction is durable. A junction box with cables allow several modules to be connected together to form a photovoltaic panel. The decision to purchase panels for a photovoltaic installation should be based on the most important mechanical and electrical parameters that determine their operation and installation .

Among the mechanical parameters of the panels are. The dimensions, strength and weight of the modules. When comparing modules characterized by the same power, special attention should be paid to selecting at the same time the smallest and lightest possible photovoltaic panels. Wise choice of panels at this stage will save us a lot of time and energy - it will be easier to arrange them on the roof (or in the garden), without putting too much strain on the roof structure .

Photovoltaic panels are exposed to various weather conditions. The load on a module from snow and wind that will not cause damage is referred to as mechanical strength. In the case of snow cap pressure, the pressure of the panel from the front is simulated, loading the panel from the back will allow testing the wind pressure. In current solutions on the market, it is accepted that the optimal strength of photovoltaic panels is 5400 Pa from the front (snow load) and 2400 Pa from the rear (wind pressure). What does this mean in the daily use of photovoltaic panels? We don't have to worry, either about the wind blowing at 130 km/h or the one-meter snow cover deposited on the panels. It is not recommended to choose panels that have worse parameters than the mentioned 5400 Pa and 2400 Pa.

When choosing photovoltaic panels, in addition to being guided by the semiconductor material - silicon, it is also worth considering the atmospheric factors in which our installation will operate. Prominent among them are. intensity of solar radiation, temperature, wind speed and also humidity and atmospheric pollution (smog). The standardization of laboratory conditions under which panels are tested has made it easier to compare the capabilities of panels from different manufacturers. The panels are tested under the following conditions (called STC Standardized Test Conditions):

The panel power obtained under STC conditions is called the power at the MMP (from Maximum Power Point). With this indicator, we have information on how much current a particular panel tested under STC conditions and with a specific area given in m2 will produce.

The power tolerance of a photovoltaic panel determines the possible deviation of the maximum power result of a given panel under laboratory conditions. We don't have to worry about anything if the panel's power tolerance value is positive. In this case, our panels can achieve a higher power than that declared by the manufacturer. The situation is quite different when the value is negative - such panels should be avoided, as the performance of the panels has probably been overstated by the manufacturers.

In datasheets, you will also encounter power in NOCT (Normal Operating Cell Temperature). This value corresponds to the power that the panels achieve under their normal operating conditions, not laboratory conditions. It is then taken into account:

It is assumed that the closer the NOCT value to the MPP, the better.

Another parameter worth paying attention to is the aforementioned efficiency. With this information we will find out what part of the radiant energy falling on 1m2 of the cell is converted into energy, It is worth deciding on panels with higher efficiency, so we can place fewer modules on the roof of our house while getting the same result if we choose panels with lower efficiency, and the entire roof will be covered with them. It is worth it to have space on the roof in case the system is expanded later.

The next parameters are the temperature power factor and the temperature of the module under NCOT conditions. The first informs us of the percentage reduction in the panel's output while its temperature increases by each 1*C from the temperature of laboratory conditions, i.e. 25*C. The temperature of the module under NCOT conditions tells us what temperature the panel will reach when operating under near real conditions.

It is worth remembering to follow the temperature power factor close to zero, and the temperature of the module under NCOT conditions should reach as low as possible, with a maximum of 45*C.

Photovoltaic panels lose their efficiency over time, the first years of their operation are 2-3% efficiency loss, the following years are about 0.6% loss per year. In this case, special attention should be paid to the linear power guarantee. By linear power guarantee is meant the minimum panel efficiency achieved at a given time. The standard is for efficiency to rank at 80% after 25 years of operation. In practice, if the efficiency of photovoltaic panels falls below 80% before 25 years, compensation can be claimed. In doing so, it is important to remember that a linear power guarantee is not a product guarantee. If the panels stop working, the manufacturer's warranty remains.

We learned about the relationship between the type of semiconductor and the efficiency of converting solar energy into electricity. We also know which parameters to pay special attention to, which type of panels will be best for our installation and weather conditions and more. But how does the photovoltaic phenomenon occur in practice and what does it consist of?

In this case, it is necessary to take a closer look at the structure of the cell itself, which consists of two layers of semiconductor. One of them is built by atoms having a higher number of electrons on the last shell, which makes it characterized by a negative charge (n-type layer). The second is built by atoms that have electron vacancies - these are called "electrons. holes (p-type layer). This layer has a positive electrical charge. The boundary of these two layers is where atoms from the n-type layer "donate" extra electrons to atoms from the p-layer by replenishing their holes. Thus, a p-n junction is formed, consisting of atoms with an inert electrical charge.

Electricity is produced in the cell only when sunlight falls on it. Solar rays are photons that have a portion of energy that, on reaching the cell, is absorbed by electrons located on the last of the electron shells of silicon atoms at the p-n junction. Electrons, as a result of the energy supplied, are precipitated from the shells and circulate through the semiconductor material (silicon) in the n-type layer. At the same time, the number of atoms with holes increases in the p-type layer. This results in the formation of a charge difference on the two layers - the voltage phenomenon occurs. Free electrons from the n layer seek to refill holes in atoms located in the p layer. The role of the insulator in this case is played by the p-n junction. Closing the electrical circuit (by connecting the receiver to the photovoltaic cell) will cause free electrons to flow toward atoms with a positive charge. This is how current is generated, and its intensity is proportional to the intensity of solar radiation, as well as the area of the photovoltaic cell.

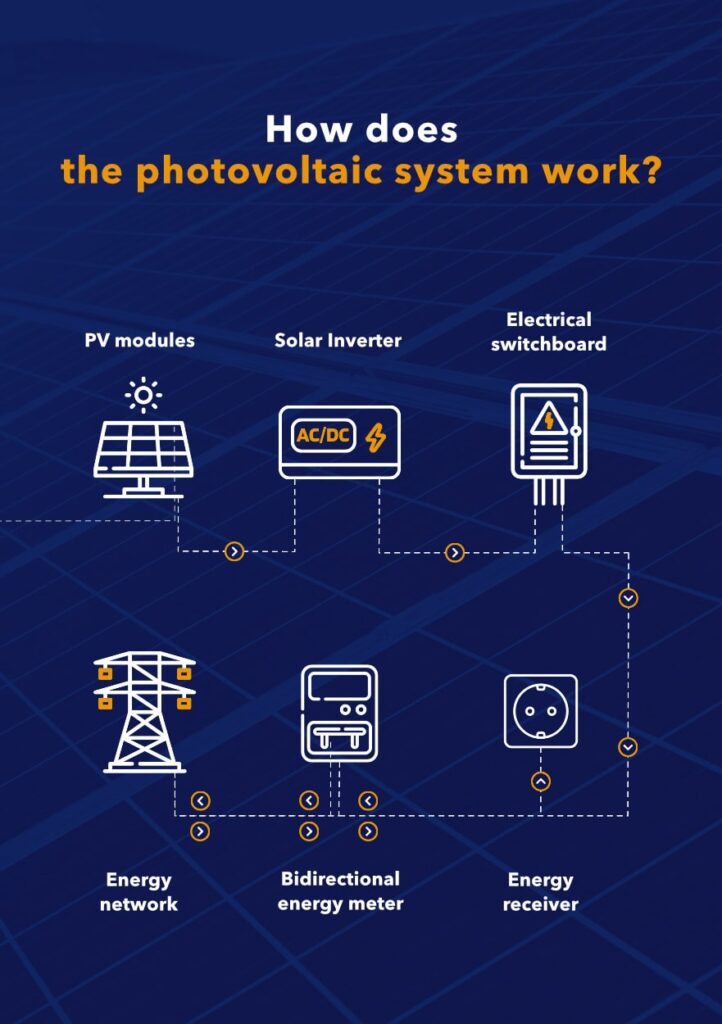

In the next step, the resulting direct current goes to the inverter, converting it to alternating current. This makes it possible to power our household appliances and consumer electronics with electricity.